The Original Alden Rig Design

Deadeyes and Lanyards

Some tasks on a large long-term project like Wolfhound sometimes takes on their own life and and lead us down surprising paths. This was the case with the Absolute Wolfhound Windlass project and this project is another example. For a “normal” yacht with a typical design and construction schedule this type of diversion may not always be possible but for a project where the journey is the goal and not the destination sometimes these side-trips and historical re-discoveries are delights to be savored.

Most sailing yachts designed and built in the 1920s had turnbuckles for rig tension and galvanized 1x19 steel wire rope for shrouds. Smaller sailboats sometimes had bronze turnbuckles and larger yachts often galvanized steel turnbuckles. Many of the finest classic yacht restorations from that era still have galvanize turnbuckles and wire rope for shrouds. Some of the turnbuckles are painted and others are just plain galvanized.

When we designed the chain plates for Wolfhound we assumed that we would be using the same type of Crossby shackles and turnbuckles as is common among many of these yachts. We made sure that the spacing between the chain plates and the diameter of the holes for the clevis pins matched the correct model of these components.

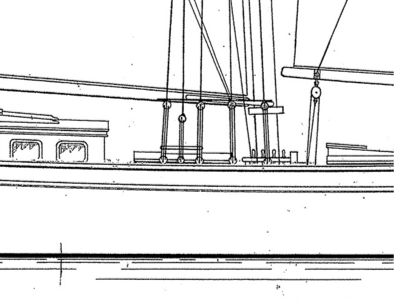

Then one day one of the followers of this project pointed out that the original John Alden rig and sail plan for Wolfhound actually had dead eyes and lanyards and not turnbuckles (see drawing on at the beginning of this BLOG entry). We didn’t pay attention to that, or we knew but discarded the idea early on, while designing the hull and chainplates? Don’t remember as it was a while ago... Although lanyards and deadeyes were rarely used on yachts in the 1920s it would have been quite likely for Wolfhound. She would possibly have been built at one of the commercial yards in Maine where fishing schooners were built. Many of the fishermen keep the use of lanyards and deadeyes until the very end of that era. They were less expensive than turnbuckles but more importantly they were considered more reliable and safer than a metal screw where the threads could become stripped under high loads with potentially disastrous consequences.

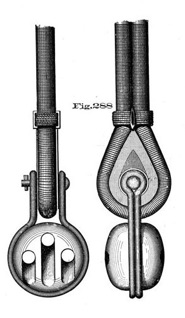

Traditional deadeyes and lanyards of various designs

The second influence to go back to deadeyes and lanyards were that one of the large classic 3-masted schooners is currently being re-rigged with dead eyes and synthetic shrouds and then we saw the video of the beautiful replica of the Fisherman COLUMBIA and she to was built with proper deadeyes. Newly inspired we decided that if they can we can too. Dead eyes it will be. However, there was just one problem, our chainplates were designed for shackles and turnbuckles and we had allowed two of the 15 pairs to be quite close to each other.

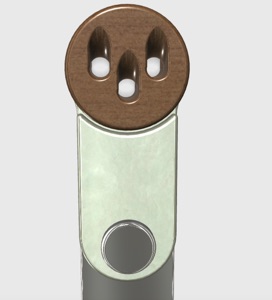

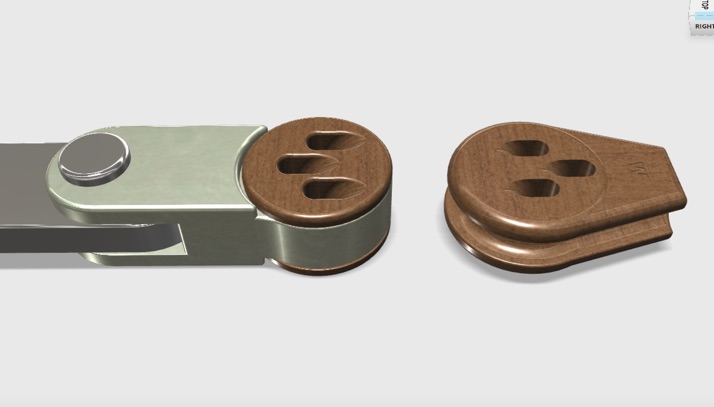

The first idea was to work around this with a very unconventional approach of integrating the turnbuckle into the Crossby shackles we already designed the the chain plates for. Structurally this is very sound but the drawback is that the dedeeyes would be oriented athwart-ships which is not traditional. We designed an unusual Lignum Vitae (wood) deadeye insert and 3D printed a few prototypes of the future Lignum Vitae wood deadeye pairs. It was an OK design but the Spectra lanyards are a lot stronger than traditional hemp line so the thin lanyards did not look right.

We then redesigned the deadeyes for larger diameter Spectra lanyards to look more authentic. These larger “eyes” would also allow us to use lanyards that were a blend of polyester and some stronger synthetic material to make it look like traditional hemp lines.

Still, gradually the idea that this would look very unconventional and not very authentic started to bother. Deadeyes have been parallel to the cap-rail on ships for 1000 years and Wolfhound would have them athwart-ships. Not quite right. Got to fix that..... It was now decided that we would totally redesign the lower dead and replace the Crosby shackles with a custom fitting so the dead eyes could be oriented parallel to the cap-rail and fit on the existing chain plates. The design was done in a few days using solid modeling CAD. A number of renderings were produced as can be seen below. The lower Lignum Vitae wood deadeye is split in half. The design is now looking a lot more authentic.

All these parts were then 3D printed in full scale in ABS plastic to verify that they fit on the actual chain plates. As can bee seen in the photos below we did that at the Graafship today and the parts fits perfectly!

We will now use the same solid modeling CAD files as we used to produce the 3D printed parts to have the metal fittings machined with a 5-axis CNC milling machine as well as fabricating a few of the deadeyes in Lignum Vitae. Following that we will load test the whole assembly including fittings, clevis pins, deadeyes, lanyards, and a shroud to verify that it meets or exceeds the rig loading safety factors that we have to meet.

The switch to deadeyes and lanyards will also save around 500 Kg of weight with the center of gravity located about 1 meter above the deck level. Later on there will be an update to this blog entry when the actual parts have been made and are tested. The silver lining of the current design is that if we in the future, for whatever reason, decide to go back for turnbuckles the chain plates can accommodate as well.

It is ironic that we ended up using solid modeling CAD design methodology and 3D printing to design deadeyes that have been used on ships for over 1000 years but that is sometimes what happens when you go down the Yellow Brick Road.

A traditional New England Fisherman with deadeyes and lanyards.

Tuesday, February 3, 2015