Exterior wood

Exterior wood (updated with video)

During the past month we have sourced wood to complete the deck, remaining deckhouses, the chain locker, the lazarette, as well as the for cap rail. We purchased 5.5 m3 of high grade Teak from VANDECASTEELE in Belgium, Europe’s largest warehouse of hard woods. It s an incredible place. The warehouse is 0.6 km long!

Teak for the cap rail and deckhouses from VANDECASTEELE warehouse for hardwoods

The default wood for deck planking on most yachts today is Teak. Teak is a great material as it has good anti-skid properties and it survives untreated outdoors for a long time due to the oils it contains. Unfortunately it is difficult to get dense old growth Teak in long lengths nowadays. Typically Teak deck planking would be 12’ long or less on a modern yacht which results in many butt joints. Having seen the original teak decks from 1939 on the Schooner EROS it is obvious what they used to look like when high quality Teak was abundant.

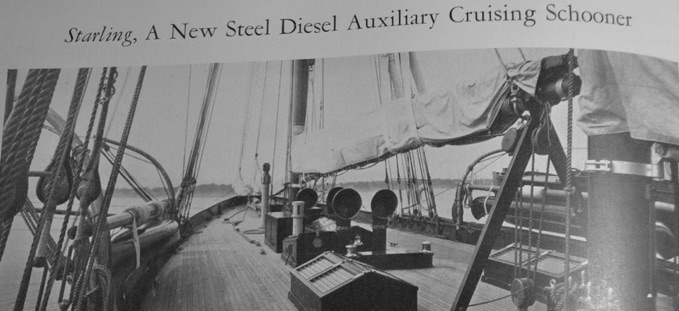

However, John Alden did not use Teak on the large schooners he designed and built mostly at commercial yards in New England in the 1920s. For design 0284 STARLING, where we have the complete specifications from the Alden archives, he used Yellow Pine and the decks were laid straight like was done on the fishing schooners (see picture from the Rudder Magazine from when STARLING was just launched in 1926). Only the sheer plank and the cap rail on STARLING was done in Teak. Unfortunately Yellow Pine is a soft wood that is turning very dark quickly and ages in a similar way to Douglas Fir (Oregon Pine).

We have pondered for several years what wood to use for the decks to make Wolfhound feel authentic but with wood more durable than Yellow Pine which is a soft wood and would age quickly where we would have to redo the decks sooner than desired. We consulted with a lot of people who had expertise in the field and there are about as many opinions of the topic as there are experts so we chartered our own territory in our quest to create something that looks and feels as authentic and unique as an Alden schooner from the 1920s.

We ended up selecting Doussie (Afzelia Doussie) which is an African hardwood from Cameron as a good substitute material for Yellow Pine. Doussie is a durable wood that will fair extremely well outdoors untreated. The only downside is that it has somewhat less favorable anti-skid properties than Yellow Pine (it is harder than Yellow Pine). When freshly milled it has a honey yellow coloring that is much closer to Yellow Pine than Teak. As it is exposed to the suns UV-light it darkens to a chestnut color (that looks quite a bit like the oil treated decks on Bluenose II), and finally it turns silver at which time it will be hard to distinguish from long length and dense VG quarter sawn Yellow Pine.

We asked the Sika Laboratories in Holland (Sika is part of 3M and is the producer of Sikaflex adhesives) to do an accelerated life time testing with temp. and humidity cycling with several of their adhesives and wood primers. The results were excellent and we ended up with several choices of adhesive and primer combinations that worked very well. Thank you SIKA.

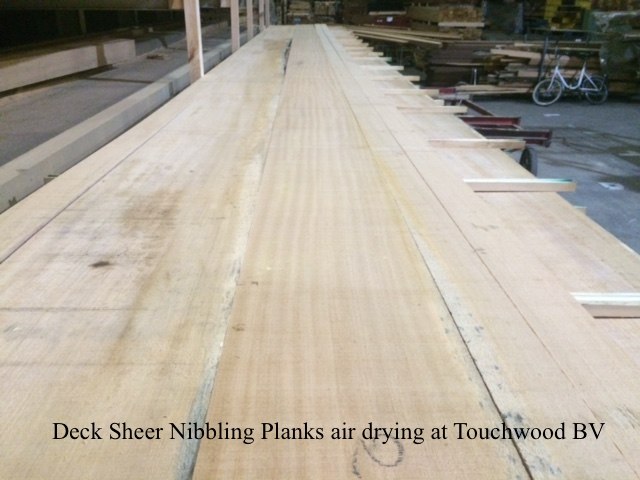

By purchasing two Doussie logs for the decks and mill it at the DECOLVENAERE mill, also in Belgium, we were able to source vertical grain 72 mm wide (3”) deck planking in 9.4 m (31’ lengths). This will results in very few but joints and a beautiful deck. We were also able to secure sheer nibbling planks that are 200 mm (8”) wide in 30’ lengths!

Afzelia Doussie wood for the deck planking in 30’ lengths

We will be laying the WOLFHOUND decks straight (like on STARLING) and without any king plank or trim around the deckhouses. Hopefully stepping on board Wolfhound in the future will result in a feeling of authenticity of a New England blue water yacht that has fishing schooner & work boat heritage and not feel like an English gentlemen's yacht, which is it not. Time will tell if our efforts will pay off and have the desired effect? It is always a bit risky when you do something that has not been done before but the same thing can be said for the whole WOLFHOUND project.

With compliments of Touchwood BV you can see a video the second milling step of the deck planks. After this step they will be air dried and then killin dried before they are milled to their final dimensions of 18 x 72 x 9400 !! There will also be some very wide deck sheer nibbling planks that are 9400 mm long!

Wednesday, November 12, 2014